Post-product packaging systems, also called post-packaging systems, include all the essential processes and machinery used after a product has been primary packaged. These systems manage critical tasks such as labeling, sealing, cartoning, boxing, sorting, palletizing, and product transportation. In modern manufacturing and logistics operations, web-based technology and smart packaging solutions play a key role by enabling automation, data collection, real-time monitoring, and system integration. These digital advancements not only improve supply chain efficiency and traceability, but also reduce human error and speed up the entire packaging process. Whether in e-commerce, food and beverage, pharmaceutical, or consumer goods industries, optimizing your post-packaging system with advanced tech can drive greater productivity and customer satisfaction.

How Web Technology Impacts Post-Packaging Systems:

Automation

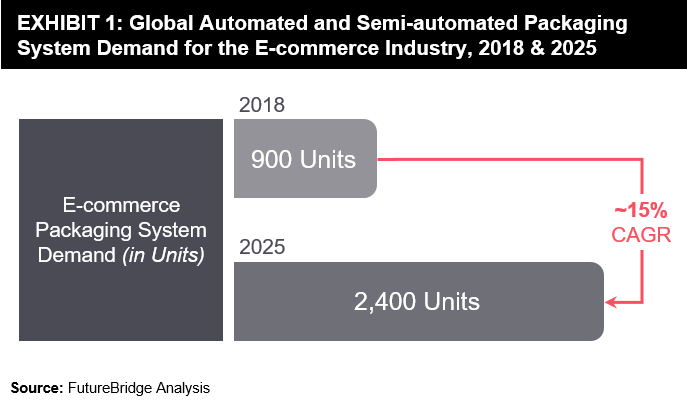

Automated packaging systems are transforming the way products are packed, offering faster, more efficient, and cost-effective solutions compared to manual packaging. These systems are broadly categorized into fully-automated and semi-automated packaging machines. Fully automated systems handle every step—from box erection, folding, sealing, to labeling—without human intervention. In contrast, semi-automated systems perform one or a few of these functions, reducing labor while still requiring some manual input.Over the past 2–3 years, the automated packaging industry has seen significant growth, largely driven by the need to reduce product damage, cut labor costs, and improve speed and consistency in packaging. Robots and smart machines are increasingly used to pack products in corrugated boxes and flexible pouches, depending on the product’s type and weight. Among these, box packaging, especially using corrugated sheets, is becoming a preferred choice for many industries due to its durability and sustainability.A major driver of this shift is the rapid expansion of the e-commerce industry. According to the United Nations Conference on Trade and Development (UNCTAD), global e-commerce sales reached $29 trillion in 2017, with projections showing a ~10% CAGR between 2018 and 2022. This surge in online shopping is creating massive demand for automated packaging solutions, both fully and semi-automated, to streamline operations and keep up with order volumes.Recent market research by FutureBridge forecasts that the market for automated packaging systems in e-commerce will grow to 2,400 units by 2025, expanding at a CAGR of 15%. Currently, fully automated systems represent around 5% of total market demand, but adoption is quickly rising as companies look to scale and optimize their packaging processes.

Image 1

Integration with e-commerce:

Web-Based Platforms:

The growing adoption of automated packaging systems among e-commerce retailers has opened up significant opportunities for packaging manufacturers looking to enter this rapidly evolving market. These smart systems address key challenges in e-commerce by improving order fulfillment speed, reducing freight and shipping costs, minimizing labor expenses, and optimizing the use of packaging materials. As online shopping continues to surge, the demand for fast, cost-effective, and eco-friendly packaging solutions is only increasing. For manufacturers, this presents a golden chance to position themselves as vital players in the booming e-commerce supply chain by delivering innovative automation-driven packaging solutions that boost efficiency and scalability.

video 1

Smart Packaging

Boosting Consumer Engagement with IoT-Enabled Smart PackagingIoT-enabled smart packaging is revolutionizing the way brands connect with consumers. By integrating QR codes, NFC tags, and other interactive technologies, companies can offer a more immersive customer experience. With just a smartphone scan, users gain instant access to product details, how-to tutorials, brand stories, or exclusive promotions. This level of transparency not only empowers consumers with valuable information but also strengthens brand trust, boosts customer loyalty, and encourages repeat purchases. As smart packaging becomes more popular, it’s becoming a powerful tool for consumer engagement in the digital age.

Supply Chain Optimization:

Integrating RFID tags and GPS tracking into packaging systems is transforming supply chain management. These smart technologies provide real-time visibility of products as they move through the entire logistics network. Businesses can monitor inventory with greater accuracy, reduce losses caused by theft, misplacement, or delays, and ensure faster, more reliable deliveries. Beyond tracking, RFID and GPS also offer valuable data insights that help optimize logistics planning, improve operational efficiency, and streamline inventory management. In today’s fast-paced market, smart tracking solutions are becoming essential tools for competitive, data-driven business growth.